12.06.2020

Listen to the blog

The restrictions applied this spring may have closed the borders for a while, but it has been great to see that our international customers’ faith in us has also continued through these uncertain times. Several completed halls have been waiting to be sent off and installed as soon as it is possible. And I’m happy to say that the time is now. When you are planning a larger hall investment, it is good to have an experienced partner who is familiar with the local building legislation and weather conditions.

Internationality has been a part of Best-Hall’s core business for 45 years. First, we headed to the Nordic countries and then continued to expand our expertise to elsewhere in Europe and to Russia. Today, our halls can be found in more than 50 countries from Northern Norway to Antarctica.

Even though Best-Hall is a strongly Finnish company, about 30–60% of our business takes place on international markets. Thanks to our extensive agent network, we have strong local competence and contacts to local construction operators in all key export countries. Best-Hall products meet the demanding international standards as well as the local building control criteria. Each hall is also dimensioned in accordance with the wind and snow loads determined in the local construction norms.

A look into the last decade of export

In my own role as an export coordinator, I get to see every day the many various purposes and needs that our steel frame structured halls are used for all over the world. I decided to study the matter a little closer and show, in numbers, what kinds of halls we have sent out into the world here from Kälviä in the past decade and where they have ended up.

And this is what I discovered.

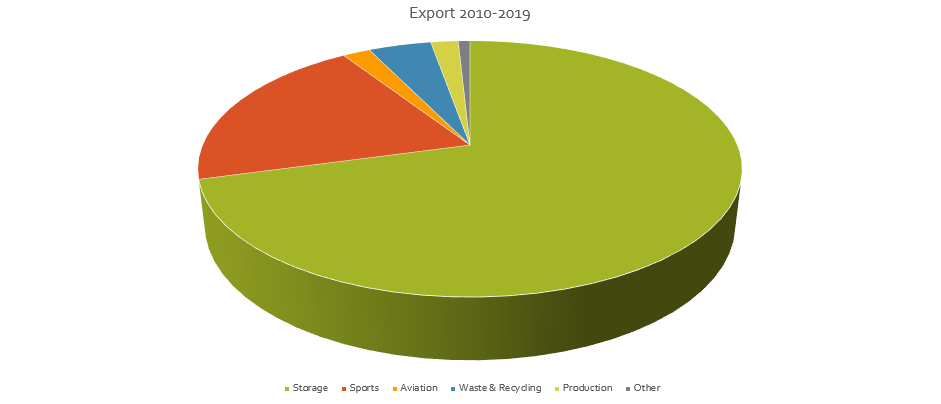

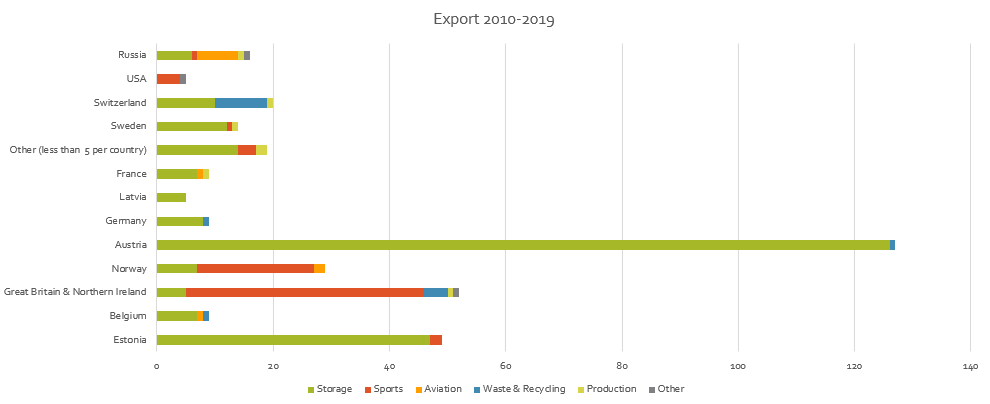

In 2010–2019, Best-Hall manufactured 363 halls for export to 25 different countries. Our halls take up a land area of more than 762,000 m2, of which around 507,000 m2 are storage halls and about 195,000 m2 are sports halls.

During the last decade, our halls have been most popular in Austria, and we have delivered more than a third of our hall stock there. Other strong export countries include Estonia, Great Britain and Norway, for example.

Versatile and adaptable storage halls have been our most sought-after product on the international markets, making up about 70% of the total export volume. This kind of storage hall solution is ideal for storing timber, for example, as the automatic air drying system guarantees a stable moisture level in the hall at all times.

Up to 20% of our export is made up by various sports halls. Flexible in its dimensions, this pillarless PVC hall with a steel frame structure is a cost-efficient solution that is ideal for a sports hall, as they can be equipped to be a cold, semi-warm or warm hall, depending on the customer’s needs. In fact, Best-Hall’s solutions are used as ice rinks, ball game halls and swimming halls alike across the world.

We have also manufactured structures such as aircraft halls, waste and recycling halls, production halls, exhibition halls – and even a casino.

Best-Hall’s advantages on international markets

Versatility is a word that describes the advantages of a steel frame structured hall well, as these halls offer nearly limitless possibilities. We strive to meet even the most demanding requests of our international customers, as a PVC hall is a surprisingly adaptable structure.

The proportion of exports in our business will continue to grow in the future.

But what makes Best-Hall an excellent partner for hall construction all over the world? Our customers have listed a few of our strengths:

I’m sure that our customers can safely continue to lean on our experience and high quality also in the future.

It is exciting to start the next decade, delivering halls around the world. Hopefully we will reach even more countries. I will be interested to see if we can deliver halls to up to a hundred different countries in the next decade! I believe we are off to a good start.

Export Sales Specialist | +358 40 183 5306

Yhdystie 3-7,

68300 Kälviä, Finland

Tel: +358 6 832 5000

info@besthall.com

Business ID FI01070190