.png)

Best-Hall uses the highest quality materials available. Many kinds of PVC-coated fabrics from all over the world are available on the market, some of which do not meet the European provisions on chemicals and non-toxicity. The fabrics used by Best-Hall are manufactured in France by Serge Ferrari and designed together with the company exclusively for Best-Hall. Serge Ferrari fabrics are undeniably the best in the world, thanks to the first-rate raw materials and patented Précontraint production method, which involves pretensioning the fabric before coating.

PVC fabric from coated polyester weave

Since coated PVC fabrics are a relatively lesser-known product, it is important to look at them a little more closely. The following will feature quite a bit of technical details on the composite material.

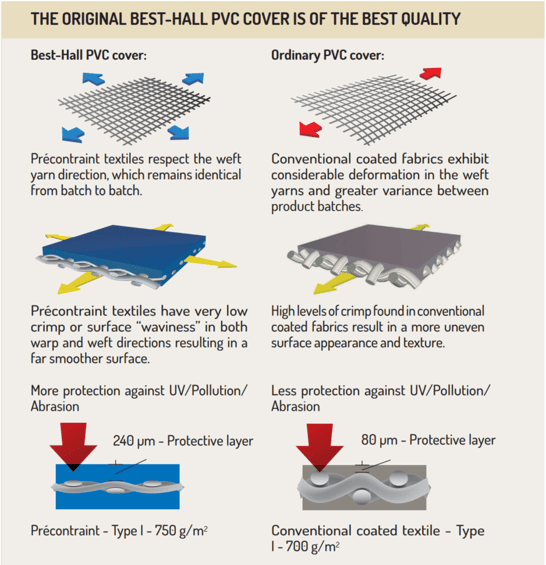

The fabric is polyester weave coated with dyed PVC. The thicker the PVC layer, the better the fabric quality, as the PVC protects the weave against sunlight and airborne pollutants, for example. The surface layer consists of either acrylic or S2 lacquer. S2 provides an excellent finish as it keeps the fabric from getting dirty, which is often the case with other finishing products. In addition to this, the fabrics have been treated with a fire retardant which prevents burning: when exposed to fire, the fabrics melt at approx. 200–300 °C. Mould formation has also been prevented.

Pretensioning to ensure quality

The weight of the fabric is generally used as an indicator of quality. This is not entirely accurate, however, as the most important factor is the thickness of the PVC coating. For example, the Flexlight 832 fabric used by Best-Hall weighs 850 g/m2, but because the fabric is pretensioned in the production phase before coating, the surface becomes smoother and accumulates a thicker and more even PVC layer. This heavier and smoother coating also protects the polyester weave better overall, since the pretensioned fabric is not as uneven as a fabric that has not been pretensioned. Non-pretensioned fabrics feature “valleys” which accumulate more of the PVC coating and “peaks” where the layer can remain very thin. At the thin spots, even slight abrasion, which is common with steel-framed buildings, may scrape off the PVC coating very quickly, exposing the weave to external stress.

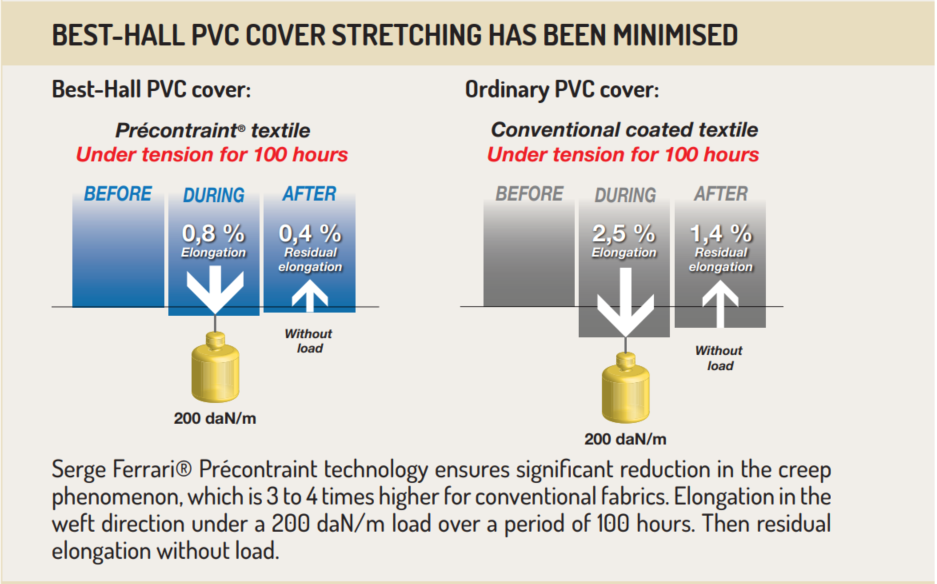

Another benefit of pretensioning is that it keeps the fabric from stretching in the same way as most fabrics do. Pretensioned fabrics stretch three times less than other fabrics. Fabrics act like any other materials: as they stretch, they get thinner. This effect has been minimised through the Précontraint method. When there is very little stretching, the surface remains more uniform and does not break.

Tested for quality and durability

Serge Ferrari tests the properties of its fabrics as they age. The latest test was conducted in La Tour du Pin in France on a Best-Hall building more than 30 years of age. The building in question was made with Flexlight 832 fabric, which has a PVC coating that is much thicker than that of any competing products. The fabric was found to have only lost about 13% of its tensile strength in 30 years. The tearing strength had only dropped to 66%. The sunny French weather had worn off half of the PVC coating, so you can imagine how abrasion and external stressors eat into the coating at the peak points mentioned above.

The fabrics used by Best-Hall feature a white back to provide brightness inside the building. Combined with the S2 treatment and pretensioned fabric, customers are sure to get the best possible value for their money.

For more information on the fabrics, contact us – after 45 years of usage, we know what we are talking about.